Over the past year or two I’ve done a bunch of experiments with the Chemigram process and even combined it with the Lumen process. In the work so far I’ve used various different substances as resists to control the action of the developer and fixer on the paper, thus influencing the pattern of the light & dark regions. Meanwhile for film processing at home I have been using my Caffenol-C-H-UK recipe almost exclusively as the developer. Caffenol is not just for film, it can be used for developing paper too and it occurred to me one day that instead of mixing up the caffenol in a jug, it might be interesting to just let the caffenol ingredients mix and react directly on the paper. So began a new series of chemigram experiments without using any kind of resist at all.

Caffenol is made by mixing washing soda crystals, vitamin C, instant coffee and optionally some iodized salt. The coffee and vitamin-C are the developing agents while the washing soda acts as an accelerator. The first step was to make a solution of washing soda and water and thoroughly soak the sheets of paper in it. The granules of instant coffee can be placed individually on the paper where needed, or simply sprinkled in an adhoc manner. The vitamin-C powder can just be poured or sprinkled onto the paper. The theory is that when the coffee/vitamin-c hits the wet paper it reacts with the washing soda to form caffenol on the surface. This is done in normal lighting conditions so the paper is universally and totally exposed and should gradually turn black where the caffenol has formed.

For this first test I used off-cuts of some outdated ~|40 year old) Ilford FB paper approx 5×4 inches in size. It was soaked in warmed (~25 C) washing soda solution then some coffee was sprinkled on, followed by some vitamin-C powder. After a minute or so it is possible to see hints of development along the edges where the paper is going dark gray

After 5 minutes the developed areas didn’t appear to be getting any darker. I figured that since the paper was quite lightweight and moderately glossy, it was probably not able to absorb very much of the washing soda solution thus limiting how much caffenol can form. The washing soda is critical as an accelerator, without it coffee/vitamin-C are far too slow. So to try and intensify things I used a syringe to squirt on some more washing soda, which made the vitamin-C fizz very nicely. This image shows the run-off is developing the paper quite efficiently after just a minute or so:

After 5 minutes the developed areas didn’t appear to be getting any darker. I figured that since the paper was quite lightweight and moderately glossy, it was probably not able to absorb very much of the washing soda solution thus limiting how much caffenol can form. The washing soda is critical as an accelerator, without it coffee/vitamin-C are far too slow. So to try and intensify things I used a syringe to squirt on some more washing soda, which made the vitamin-C fizz very nicely. This image shows the run-off is developing the paper quite efficiently after just a minute or so:

The surprise came when I decided to wash off the ingredients. It turned out that the instant coffee had formed quite a sticky sludge which had adhered well to the paper. Given the limited water holding capacity of the paper, the areas with great concentrations of coffee granules had ironically developed the least. There is just a slight gray speckling effect where the coffee had a very limited action on the silver halides. The areas of most intense development were along the edges where the coffee and vitamin-C had mixed initially, and then in the broad areas of run-off which had well mixed caffenol

The process was repeated, but without pouring washing soda over the ingredients, just relying in that initially absorbed by the paper. The results were fairly similar to the first test, but with less development of the surrounding paper, as would be expected due to lack of run-off.

The results obtained were partially aligned with the initial expectations of the process but, as always when experimenting, there were surprises. In particular the inability of the paper to absorb sufficient washing soda solution was a key limiting factor in the results. It was surprising to see how the coffee + vitamin-C alone were fairly weak, but when they combined they became stronger than the sum of the parts. Finally the way the coffee became a sticky mass on the surface of the paper actually caused it to act as a chemigram resist, as well as a developer at the same time!

The results obtained were partially aligned with the initial expectations of the process but, as always when experimenting, there were surprises. In particular the inability of the paper to absorb sufficient washing soda solution was a key limiting factor in the results. It was surprising to see how the coffee + vitamin-C alone were fairly weak, but when they combined they became stronger than the sum of the parts. Finally the way the coffee became a sticky mass on the surface of the paper actually caused it to act as a chemigram resist, as well as a developer at the same time!

With the initial experiments successfully completed it was time to try some larger scale work with full sheets of 8×10 paper. The goal was really to just do more of the same but on a larger scale. The first work was fairly light on washing soda, thus forming broadly static patterns showing the texture of the vitamin-c powder and coffee granules, though there were some limited areas of runoff creating dynamic swirling patterns

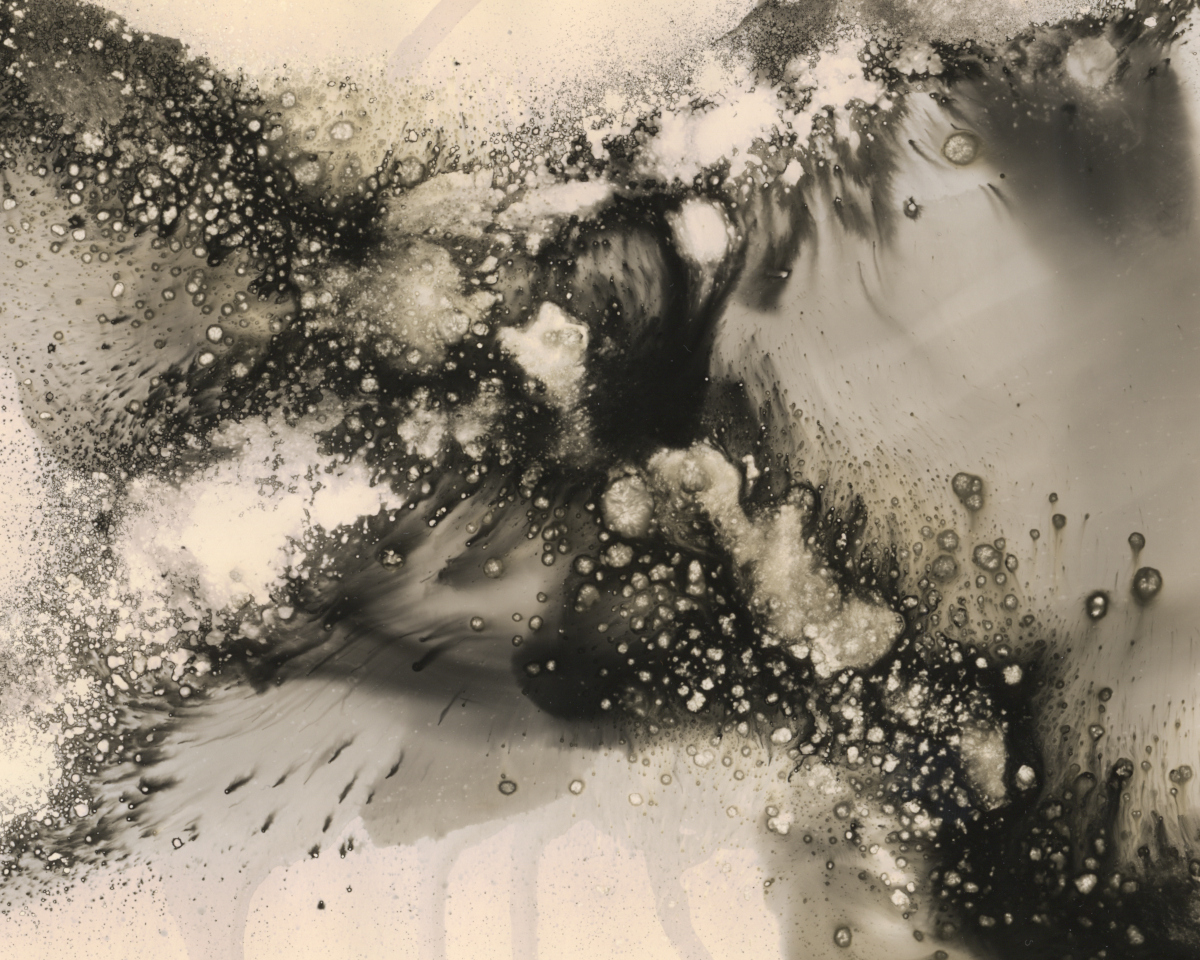

With the second print the aim to was make a very dynamic image showing the motion of developing liquid on the surface of the paper, at the expense of any fine detail.

With the second print the aim to was make a very dynamic image showing the motion of developing liquid on the surface of the paper, at the expense of any fine detail.

Pleased with the results of caffenol in a pure chemigram process, I decided to take it a step further and try to combine chemigram with a traditional B&W development process in the darkroom.

Pleased with the results of caffenol in a pure chemigram process, I decided to take it a step further and try to combine chemigram with a traditional B&W development process in the darkroom.

A while ago I took an simple photo of the Moon with a DSLR and teleconvertors which I then used to create a digital negative on acetate for printing as a cyanotype. Astrophotography is an increasingly popular endeavour for many people, but almost without exception the aim is to produce images with the best sharpness and finest detail the equipment will allow. An unfortunate result is that any two images of the moon will look broadly alike, and my own astrophotography images of the moon are no exception. So I decided that this digitally captured moon image would provide a good challenge as source material for creating a truly unique photographic print.

In the darkroom under safe light conditions, I placed a sheet of outdated Ilford FB 8×10 paper under the enlarger. The digital negative went on top of the paper for purpose of contact printing. From previous experience contact printing on this paper I just guesstimated the exposure at 15 seconds, with lens at f/8. The paper now has an invisible latent image ready to be worked on by the caffenol.

I soaked the paper in a washing soda solution, randomly sprinkled instant coffee and vitamin-C onto the paper and then just let it sit for a few minutes to give time for the caffenol to start working. Part way through I also added a very small amount more washing soda in some areas to encourage the development. After approximately 3-4 minutes (I wasn’t really timing this) I could see slight hints of the paper starting to turn gray in places. Washing off the caffenol residue though showed almost no development across most of the paper, which was initially disappointing.

None the less I now put the print through a regular B&W dev, stop & fix process. Rather than leaving it in the developer for the full 1 minute though, I noticed it was developing quite fast and choose to just move it to the stop bath when it “looked about right” – about 35 seconds. What was happening was that although not really visible yet, the caffenol had indeed kickstarted the development across the paper and the normal developer was just needing to finish off the process. If I had let the image site in the developer for the full 1 minute it would have been over developed and lost some of the qualities of the caffenol granulation.

The result was thus incredibly pleasing image of the moon, which I hereafter title “Moon through a dirty window”

Looking at the results obtained shows that the idea of using caffenol in a chemigram process has great possibilities for image making. On its own it can be semi-controlled to create attractive abstract images, while when combined with a regular B&W printing process it turn an otherwise plain image into an intriguingly textured pleasing artwork. I’m very much looking forward to getting back in the darkroom to further work through the possibilities this offers

Looking at the results obtained shows that the idea of using caffenol in a chemigram process has great possibilities for image making. On its own it can be semi-controlled to create attractive abstract images, while when combined with a regular B&W printing process it turn an otherwise plain image into an intriguingly textured pleasing artwork. I’m very much looking forward to getting back in the darkroom to further work through the possibilities this offers